Developing a multi-location Smart Inventory Management System for a leading Tobacco Supplier

About The Project

- Industry

- Region

- Client since

- Logistics

- USA

- 2018

The client, a reputed and progressively growing tobacco brand based in Rajasthan with one of the largest tobacco production facility in the region, was looking to deal with the problem of inventory management. Running a business on a large scale was making it difficult to get data about the stock in production, in the warehouse, stock-in-market, sold stock, etc.

The client was using a manual system to manage different aspects but top management was finding it difficult to forecast inventory status. The client was in favor of a digital inventory management system and collaborated with Team Sufalamfor development of a robust inventory management system.

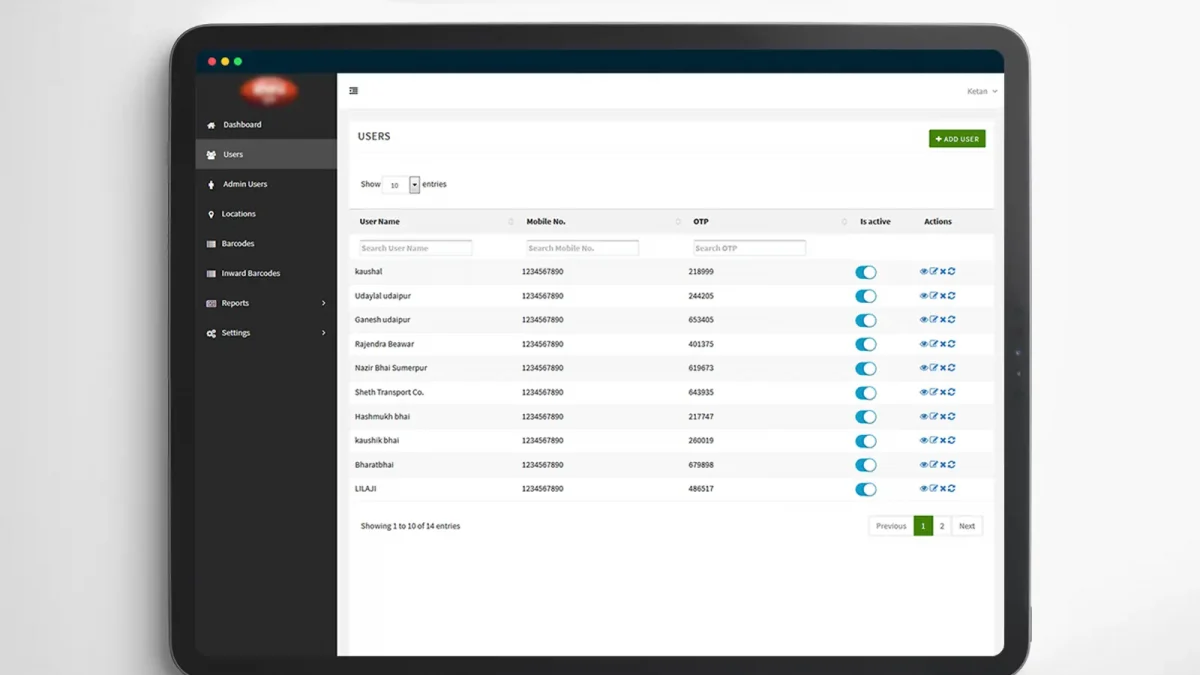

Solution Offered

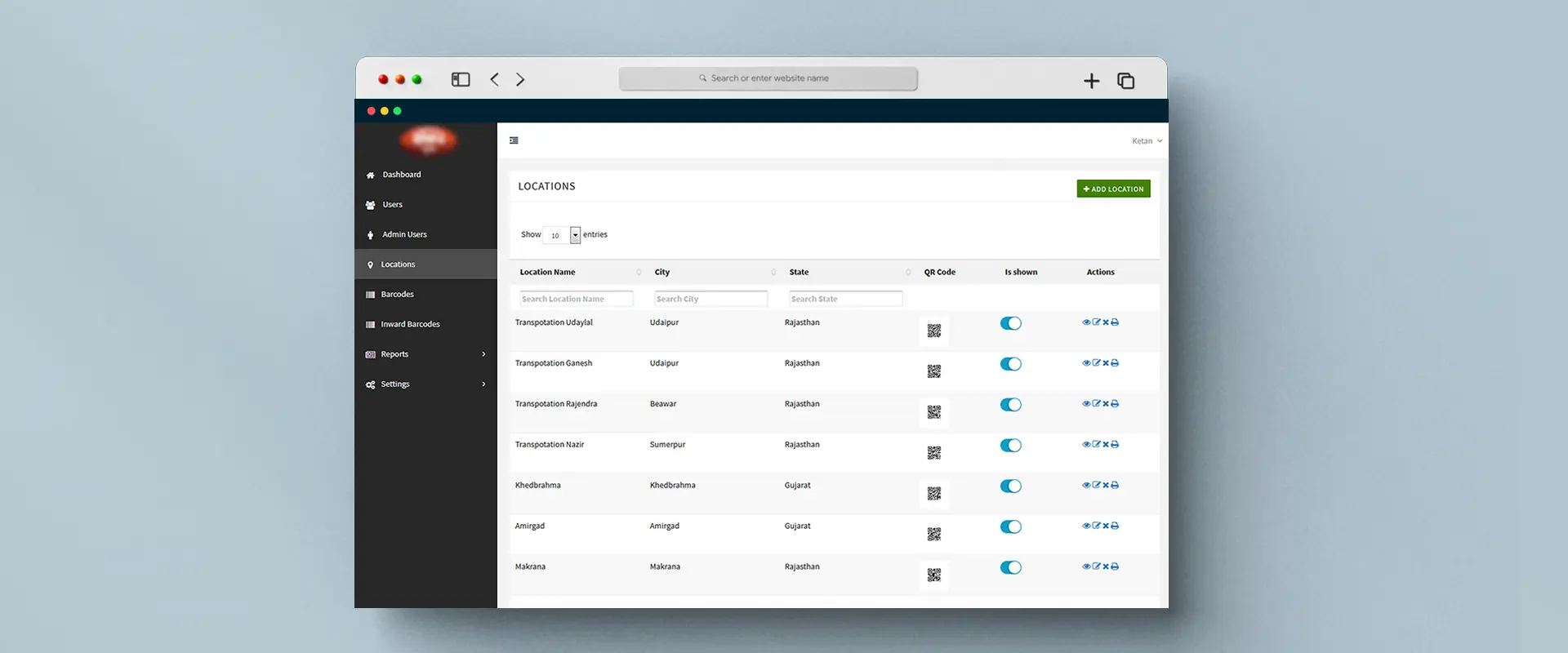

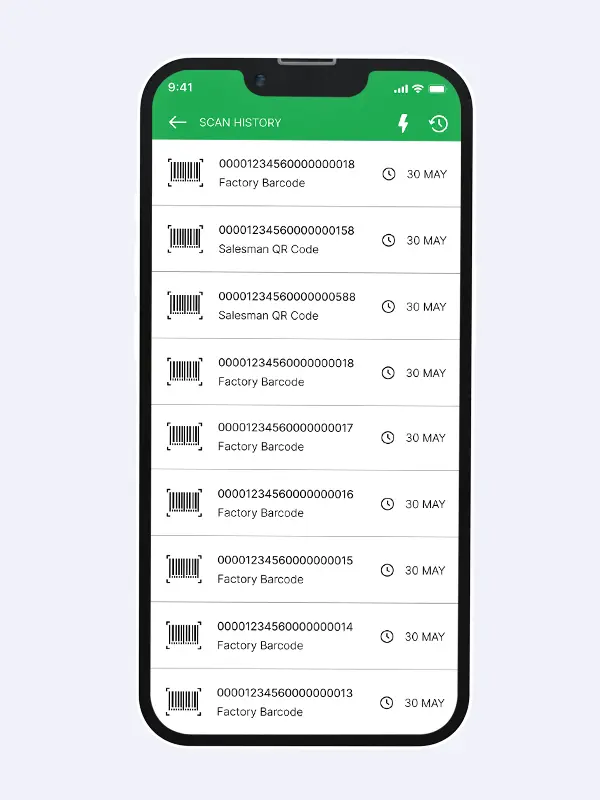

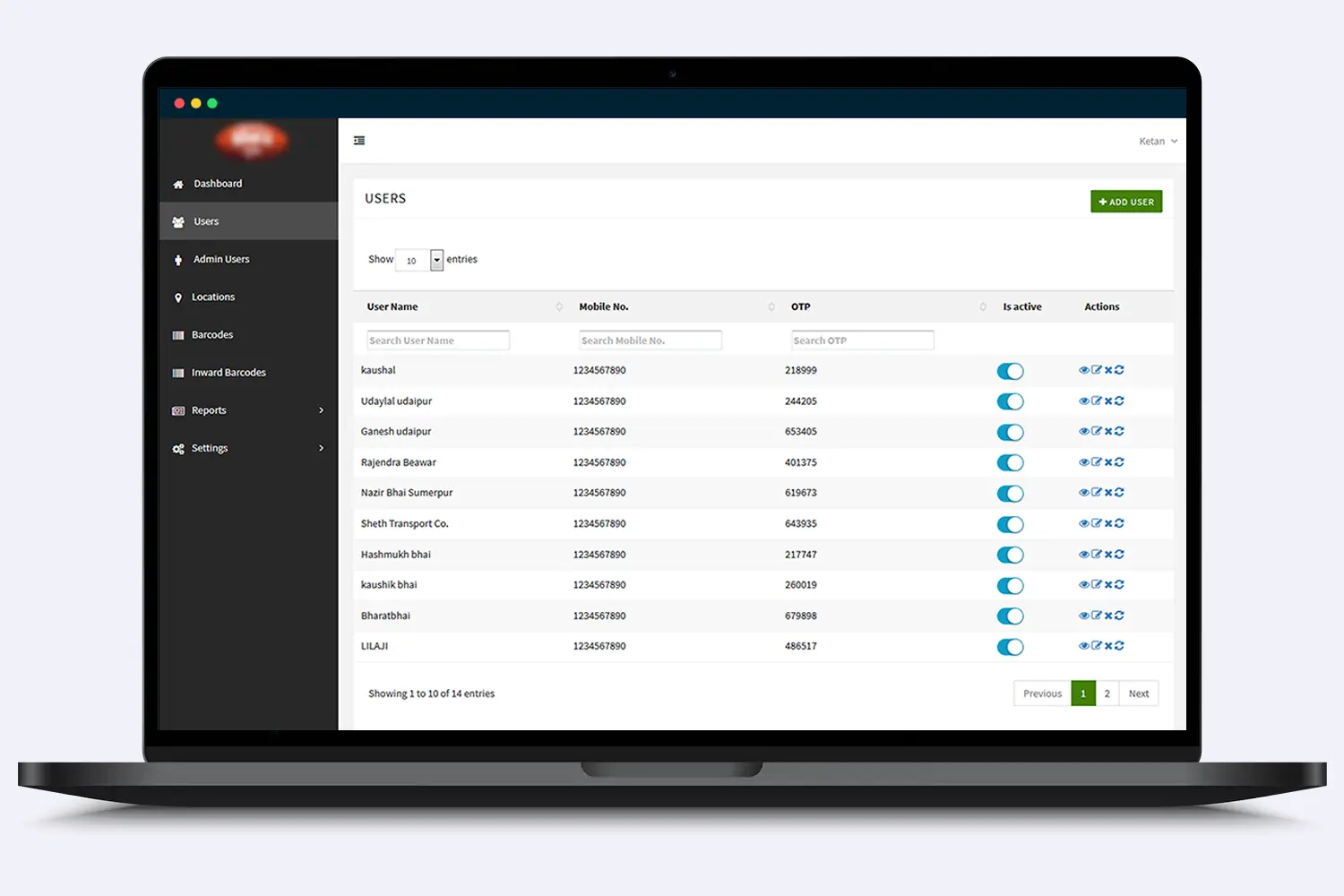

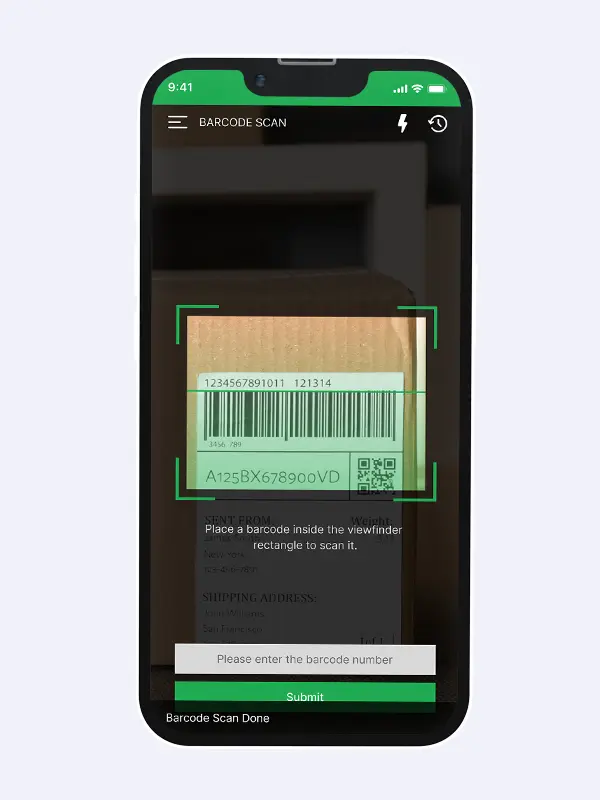

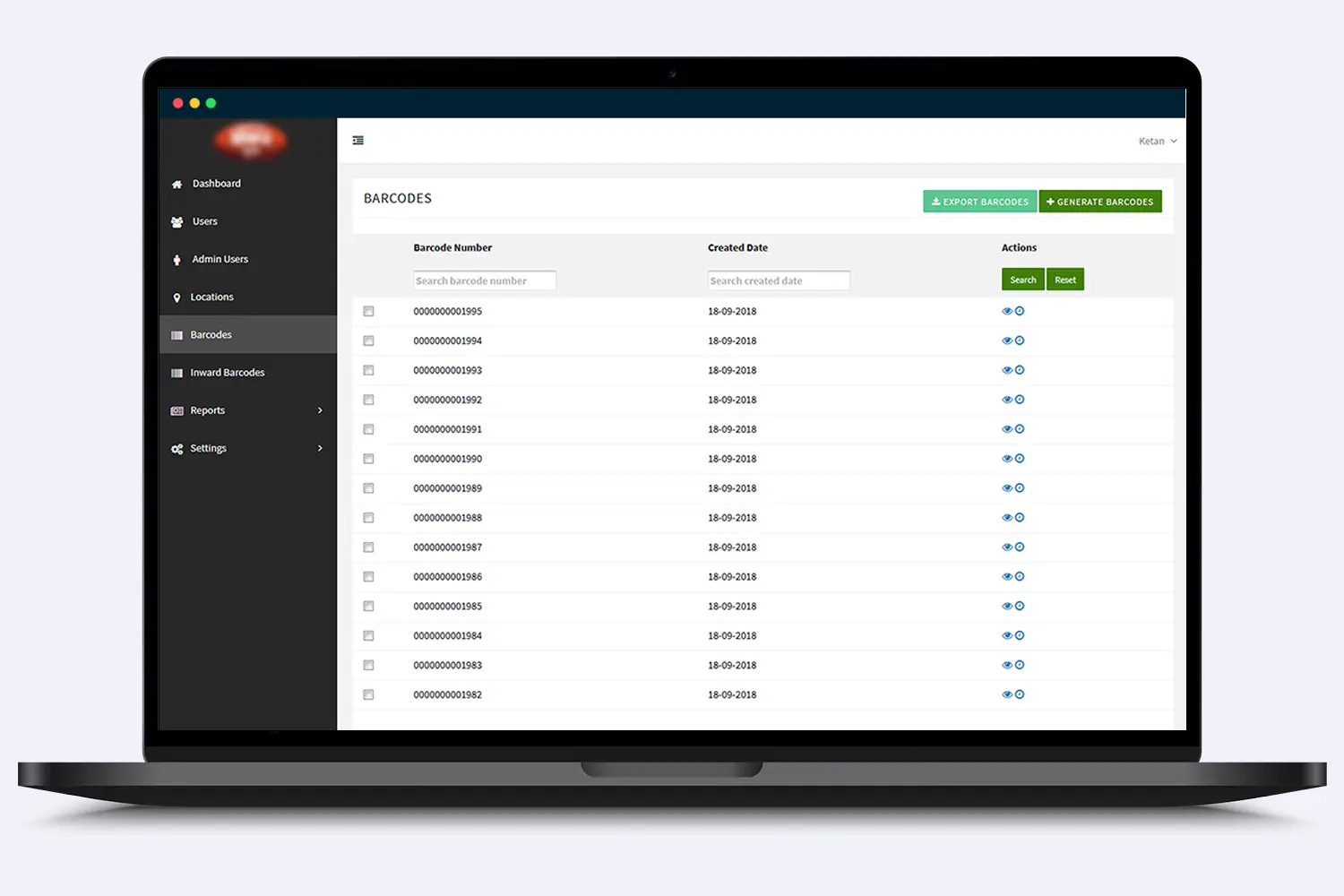

Sufalam analyzed the client’s requirement and recommended a full-suite inventory management system to handle various aspects of supply chain management. As the client had to deal with manual paperwork and take counts manually, it was suggested that the solution would transform the operations entirely and use bar code hardware to take stock and automate reporting. The solution was developed as a standalone inventory system with several features that were specific to the client’s business model and requirements.

Objective

- Development of a digital inventory management system for managing inventory, asset and warehouse.

- Creating an asset tracking system to enhance real-time visibility of stock levels and order status

Key Features

- Standalone inventory management

- Inventory optimization

- Kitting and creation of bill of materials

- Real-time batch traceability

- Vendor-managed inventory

- Reporting and analytics

- Demand forecasting

Solution Benefits

The solution developed by Sufalam offered the following benefits to the client:

- Real-time inventory reports: Clientwasable to practice full control over supply chain management and was able to identify inventory trends, stock-on-order and supply on-time performance.

- Prompt Order Fulfillment: The hassles associated with manual data entry were reduced making the whole order fulfillment process faster, productive and cost-efficient.

- Customized suite:The solution was designed catering to the personalized requirements of the client making it much more efficient at handling client’s needs when compared to standard packages.

- 40% increase in inventory turnover: The implementation of the solution improved inventory efficiency augmenting the client’s growth plans.

Tools Technologies Used

Various tools and technologies are employed in developing applications, enabling efficient workflows and enhanced user experiences.